-

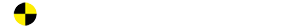

Turnkey projects building fatigue test laboratories. This includes, basic lay out, design of foundation, design of load frames fixtures, specifications of test equipment, evaluation of tender offers, training of manpower, proving of test setup. Guidance on selection of appropriate technologies etc.

Design, development, integration of test setup for application. Such as shock absorber test rigs, steering test rig, load frames for single axis or multi axis component testing.

Training of engineers.

Guidance on passive safety requirements.

Automotive test rig development.

Testing of vehicle components for fatigue at Sincotec GmbH, Germany (Such as Crank shaft, Con rod, knuckles, Chains, Railway wheel, Wheel hub, etc.).

-

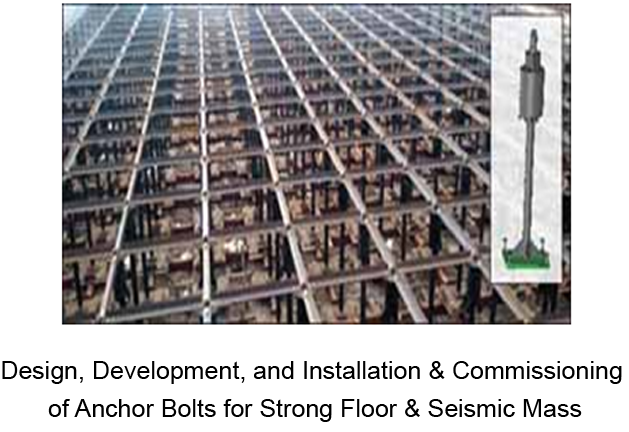

Vibration Isolation System.

Project: Design, Development, Installation & Commissioning of Vibration Isolation System.

Seismic Mass weight – 1000 MT

Natural Frequency – less than 1 Hz

-

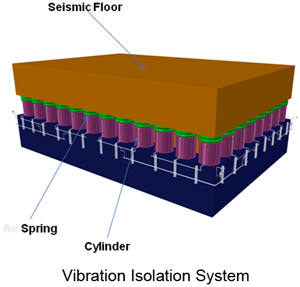

Project: Design, Development, Installation & Commissioning of Portable Modular Load Frame.

Loading Capacity – 250 kN

Features – Motorized lifting & lowering of cross beam

-

H1-H2 Test Rigs

H1-H2 Test rig system is a Bus seat test compliant with AIS-023. The system consists of rigid frame structure for seat testing up to 3 stations. Bed plate is used to mount bench seats. It is designed with advanced control system with precise load control mechanism. The electrical actuators reduces maintenance.

-

Calspan

Installation, Commissioning & Service Support to Calspan Inc, USA for building NATRIP’s Crash Test Facilities in India.